Ngwa igwe eji egbutu isi nke cylinder-C diamond imi

Foto ihe

Nkọwa nke ihe

Uru: 1. Diamond material, adịghị mfe deform.2. Obere uzuzu, nchebe gburugburu ebe obibi.3. Akwa manganese ígwè, thickened matrix.4. A na-emepụta mkpanaka na-eme ka ọ dịkwuo ogologo ndụ ọrụ.

Ihe aha: Diamond egweri Isi

Ihe Nlereanya: Bọọlụ Nosed Cylinder-C

Isi ihe: diamond

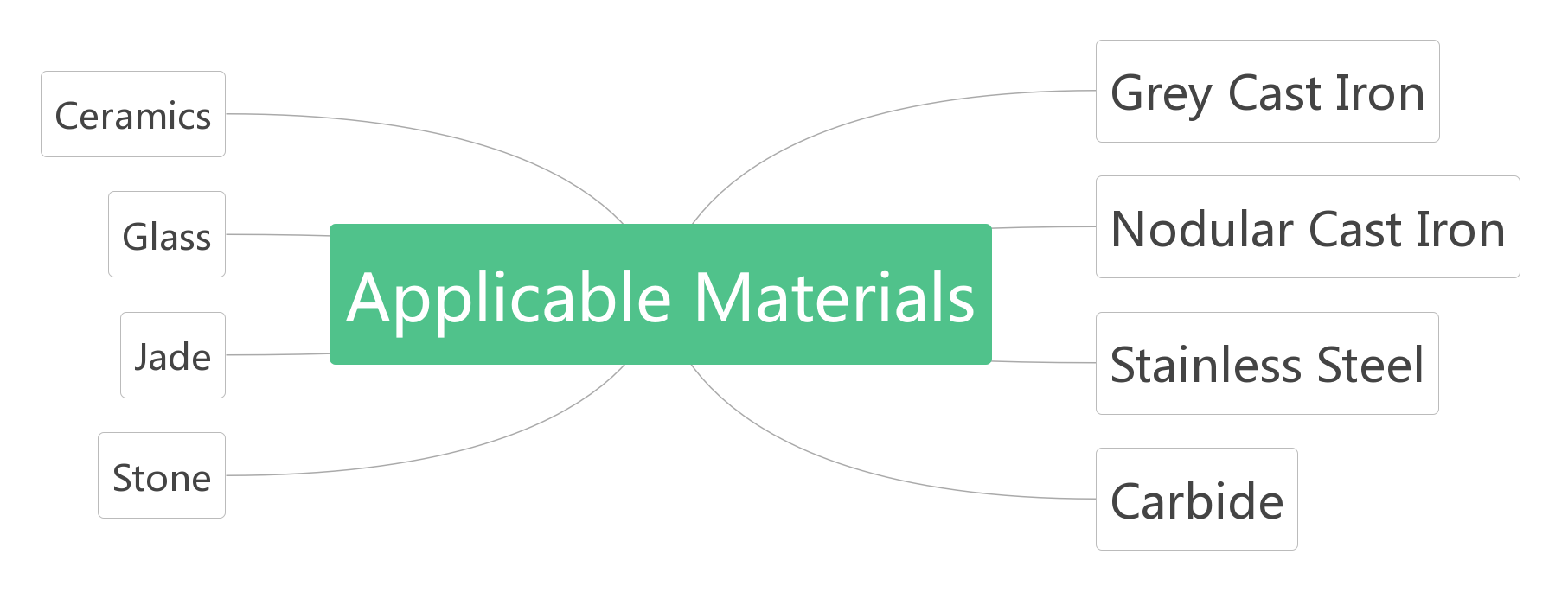

Ngwa ihe:

1. Akụkụ ebu bụ ala ma na-egbu maramara.

2. Egweri: n'ozuzu eji maka egweri burr nke workpiece, ma ọ bụ machining n'elu workpiece na ala nkenke Jiri egweri igwe, electric, pneumatic na ngwaọrụ ndị ọzọ na-arụ ọrụ na elu na-agba iji nweta egweri mmetụta.

3. Polishing: a na-eji ya maka nhazi na ihe dị elu chọrọ maka imecha elu (roughness).Ọ bụ usoro chọrọ nhazi iche.

Isi dayameta: 6mm/8mm/12mm/14mm/16mm/18mm/20mm

Ogologo isi: 27mm

Ogologo ogologo: 33mm

Ihe Ọdabara Ngwa

Ngwa ngwa

1. Nhazi nkume

2. Nhazi iko

3. Uwe ejiji na-egweri, ihe ndị na-emegharị emegharị, ngwaahịa ciment

4. Eji egweri, polishing na egweri6. The ebu akụkụ na-ala na-egbu maramara

5. A na-etinyekarị ya na igwe ihe, igwe ihe, ihe nrụnye ma ọ bụ ngwaọrụ nrụnye pụrụ iche.A na-eji ya eme ihe na anya anya anya, prisms, iko elekere, iko sapphire.

Akụkụ akụkụ

| Nlereanya | Dayameta | Mgbakọta Ogologo | Ogologo ọrụ | Ogologo ogologo | Dayameta Shank |

| Silinder Nosed 6*6 | 6mm | 60mm | 27mm | 33mm | 6mm |

| Cylinder Nosed Bọọlụ 6*8 | 8mm | 60mm | 27mm | 33mm | 6mm |

| Silinda imi bọọlụ 6*10 | 10mm | 60mm | 27mm | 33mm | 6mm |

| Cylinder Nosed Bọọlụ 6*12 | 12mm | 60mm | 27mm | 33mm | 6mm |

| Cylinder Nosed Bọọlụ 6*14 | 14mm | 60mm | 27mm | 33mm | 6mm |

| Silinder Nosed 6*16 | 16mm | 60mm | 27mm | 33mm | 6mm |

| Silinda imi bọọlụ 6*18 | 18mm | 60mm | 27mm | 33mm | 6mm |

| Silinda imi bọọlụ 6*20 | 20mm | 60mm | 27mm | 33mm | 6mm |

Ọdabara Ọnọdụ

Ntụle ngwaahịa

Brazing egweri isi

● Ogologo ndụ ogologo ndụ, na-adịgide adịgide karịa isi egweri nkịtị

● Uzuzu na-adịchaghị ala, na-emekọ ihe na gburugburu ebe obibi

● Ngwuri dị nkọ na arụmọrụ dị elu

● Ngwongwo manganese dị elu, matriks siri ike

Omenala egweri isi

● Ndụ ọrụ dị mkpirikpi, nchekasị na-enweghị isi ga-emepụta nrụrụ

● Uzuzu buru ibu, na-emerụ ahụ mmadụ

● Ndụ ọrụ dị mkpirikpi, ngbanwe akwụkwọ ntuziaka na-ewe oge ma na-arụsi ọrụ ike

● Aka ihe nkịtị, ọ dị mfe imebi, nguzozi adịghị mma

Uru ngwaahịa

1. Anyị bụ ndị ọkachamara carbide burr emeputa kemgbe 1992. Na 30 afọ nke egweri ngwaahịa nke ahụmahụ.

2. Anyị ga-enyocharịrị ngwaahịa niile.

3. Ngwaahịa niile dị na ngwaahịa.

4. Anyị na-enye free shank logo na free akara na ngwaahịa.

Uru diamond egweri isi

1. High egweri arụmọrụ:

Mgbe ị na-egweri carbide cimented, arụmọrụ ya na-egweri dị ọtụtụ okpukpu karịa nke silicon carbide.Mgbe ị na-egweri W12 cr4v4mo, igwe na-agba ọsọ na-arụ ọrụ na-adịghị mma, nkezi arụmọrụ na-abawanye karịa ugboro 5.

2.High eyi nguzogide:

wiil ndị na-egweri diamond nwere nguzogide dị elu yana oriri abrasive dị ala, ọkachasị mgbe a na-egwe ihe arụrụ arụ siri ike na nke na-emebi emebi.Mgbe a na-egweri ígwè na-egweri na diamond egweri wheel, ya eyi iguzogide bụ 100 ~ 200 ugboro nke izugbe abrasive;

3. The egweri workpiece nwere elu nkenke na ezi elu àgwà

Mgbe ị na-egweri ngwaọrụ carbide cemented na wheel igwe na-egweri diamond, adịghị ike nke elu agụba na agụba dị nnọọ ala karịa nke wiil carbide borax.Oghere arc nke agụba ahụ dị obere, agụba ahụ dịkwa nkọ.Ịdị ogologo nke ngwá ọrụ nwere ike ịbawanye ugboro 1 ~ 3.The roughness nke workpiece esichara site diamond egweri wheel nwere ike n'ozuzu iru 0.1 ~ 0.025 μ m.Tụnyere na nkịtị egweri wheel egweri, imecha nwere ike mma site 1 ~ 2 etoju.