Osisi Nosed Bọọlụ-F Ngwa diamond Na-egweri Isi-Abrasive Ngwa

Foto

Nkọwa ndị bụ isi

Aha: Diamond egweri Head

Ụdị: Osisi Nosed Ball-F

Isi ihe: diamond

Ngwa: 1. Akụkụ ebu bụ ala ma na-egbu maramara.2 Deburring na trimming nke igwe anaghị agba nchara.3 Nhazi mmezi oghere anwụ anwụ.4 Slotting na egweri akụkụ ígwè.

Isi dayameta: 8mm/10mm/13mm/15mm/18mm/20mm

Ogologo isi: 30mm

Ogologo ogologo: 30mm

Uru: 1. Diamond material, adịghị mfe deform.2. Obere uzuzu, nchebe gburugburu ebe obibi.3. Akwa manganese ígwè, thickened matrix.4. A na-emepụta mkpanaka na-eme ka ọ dịkwuo ogologo ndụ ọrụ.

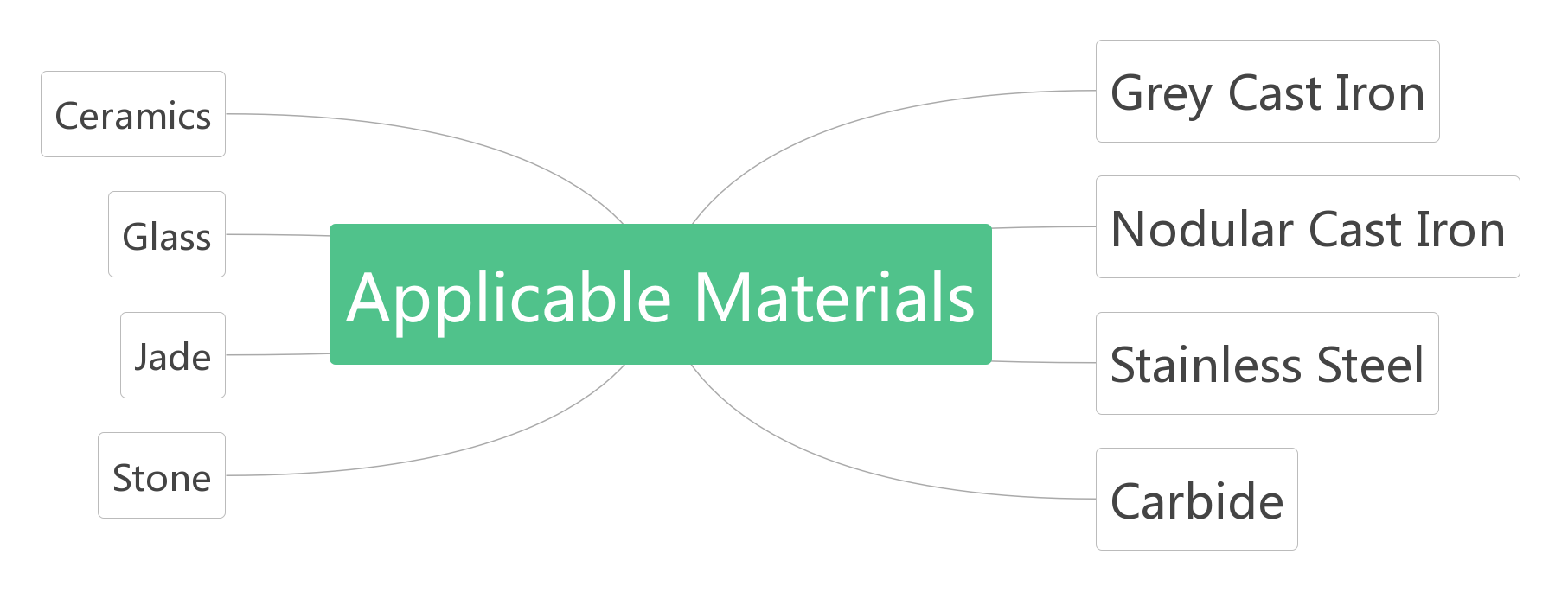

Ihe Ọdabara Ngwa

Ngwa ngwa

1. Nhazi na mmezi nke ebu.

2. Ihe osise nkume, ihe osise, ịcha ahịrị, na-egweri, igwu mmiri.

3. Ihe osise iko.

4. Nhicha nke nkedo, akpụ, welding n'akụkụ, burrs, welds.

5. Nhazi nha nha nha.

6. Akụkụ ebu bụ ala ma na-egbu maramara.

7. Deburring na trimming nke igwe anaghị agba nchara.

8. Nwunye nrụzi nhazi.

9. Slotting na egweri akụkụ ígwè.

Akụkụ akụkụ

| Nlereanya | Dayameta | Mgbakọta Ogologo | Ogologo ọrụ | Ogologo ogologo | Dayameta Shank |

| Osisi imi bọọlụ 6*6 | 6mm | 60mm | 30mm | 30mm | 6mm |

| Osisi imi bọọlụ 6*8 | 8mm | 60mm | 30mm | 30mm | 6mm |

| Osisi imi bọọlụ 6*10 | 10mm | 60mm | 30mm | 30mm | 6mm |

| Osisi imi bọọlụ 6*13 | 13mm | 60mm | 30mm | 30mm | 6mm |

| Osisi imi bọọlụ 6*15 | 15mm | 60mm | 30mm | 30mm | 6mm |

| Osisi imi bọọlụ 6*18 | 18mm | 60mm | 30mm | 30mm | 6mm |

| Osisi imi bọọlụ 6*20 | 20mm | 60mm | 30mm | 30mm | 6mm |

Ọdabara Ọnọdụ

Ntụle ngwaahịa

Brazing egweri isi

● Ogologo ndụ ogologo ndụ, na-adịgide adịgide karịa isi egweri nkịtị

● Uzuzu na-adịchaghị ala, na-emekọ ihe na gburugburu ebe obibi

● Ngwuri dị nkọ na arụmọrụ dị elu

● Ngwongwo manganese dị elu, matriks siri ike

Omenala egweri isi

● Ndụ ọrụ dị mkpirikpi, nchekasị na-enweghị isi ga-emepụta nrụrụ

● Uzuzu buru ibu, na-emerụ ahụ mmadụ

● Ndụ ọrụ dị mkpirikpi, ngbanwe akwụkwọ ntuziaka na-ewe oge ma na-arụsi ọrụ ike

● Aka ihe nkịtị, ọ dị mfe imebi, nguzozi adịghị mma

Uru

1. Anyị bụ ndị ọkachamara carbide Burr emeputa kemgbe 1992. Na 30 afọ nke ọnwụ ọnụ nna ukwu, na-egweri oge nke workpieces bụ maa ogologo karịa nke ndị ọzọ.

2. Anyị nwere ndị ahịa si Europe, dị ka: Spain, Netherlands, Germany , Croatia , Romania , Lithuania, Poland na na, na ndị ọzọ South America na Southeast Asia.Our ngwaahịa na-ekpo ọkụ na-ere n'ụwa nile, na ọ dịghị nzaghachi banyere isi gbajiri agbaji.Ọtụtụ ndị ahịa na-emeghachi usoro ahụ kwa ọnwa.

3. Ụfọdụ koodu mgbe niile nwere ngwaahịa na enwere ike ibupu ya n'ime ụbọchị 7!

Uru diamond egweri isi

1. Nhazi eruba: Na sintering usoro, e nwere a kemịkalụ njikọ n'etiti taya ígwè na diamond particles, na n'otu oge ahụ, nsonye ogo dị elu, na diamond adịghị mfe ịdapụ, n'ihi ya, ọ na-enwe ezigbo eyi iguzogide. na ogologo ndu.

2. Uru: n'ihi na elu hardness ihe na ájá gụnyere nkedo, otu ibe hà 100-300 nkịtị resin egweri iberibe.

3. Nchekwa gburugburu ebe obibi: abrasive enweghị sọlfọ, ọ dịghị adapụ, na uzuzu na mkpofu gas mmetọ bụ fọrọ nke nta efu.

4. Nchekwa: A na-anabata matrix ígwè dị elu, ọ dịghịkwa ihe ize ndụ nwere ike ime site na irighiri ihe na-efe efe.